Electric recreational vehicle manufacturer Lightship has begun production of its AE.1 Cosmos Edition. The model is officially sold out, and deliveries to customers are to begin by the end of summer 2025.

For its next act, the company has introduced two new trim offerings for its flagship all-electric travel trailer: the AE.1 Atmos and AE.1 Panos. Both are designed and manufactured in the United States.

“The Cosmos Edition proved that the market is hungry for electric RVs that don’t compromise on performance or design,” said Toby Kraus, Lightship co-founder and CEO. “Atmos and Panos bring our vision of sustainable adventure to more families and adventurers, regardless of their camping style.”

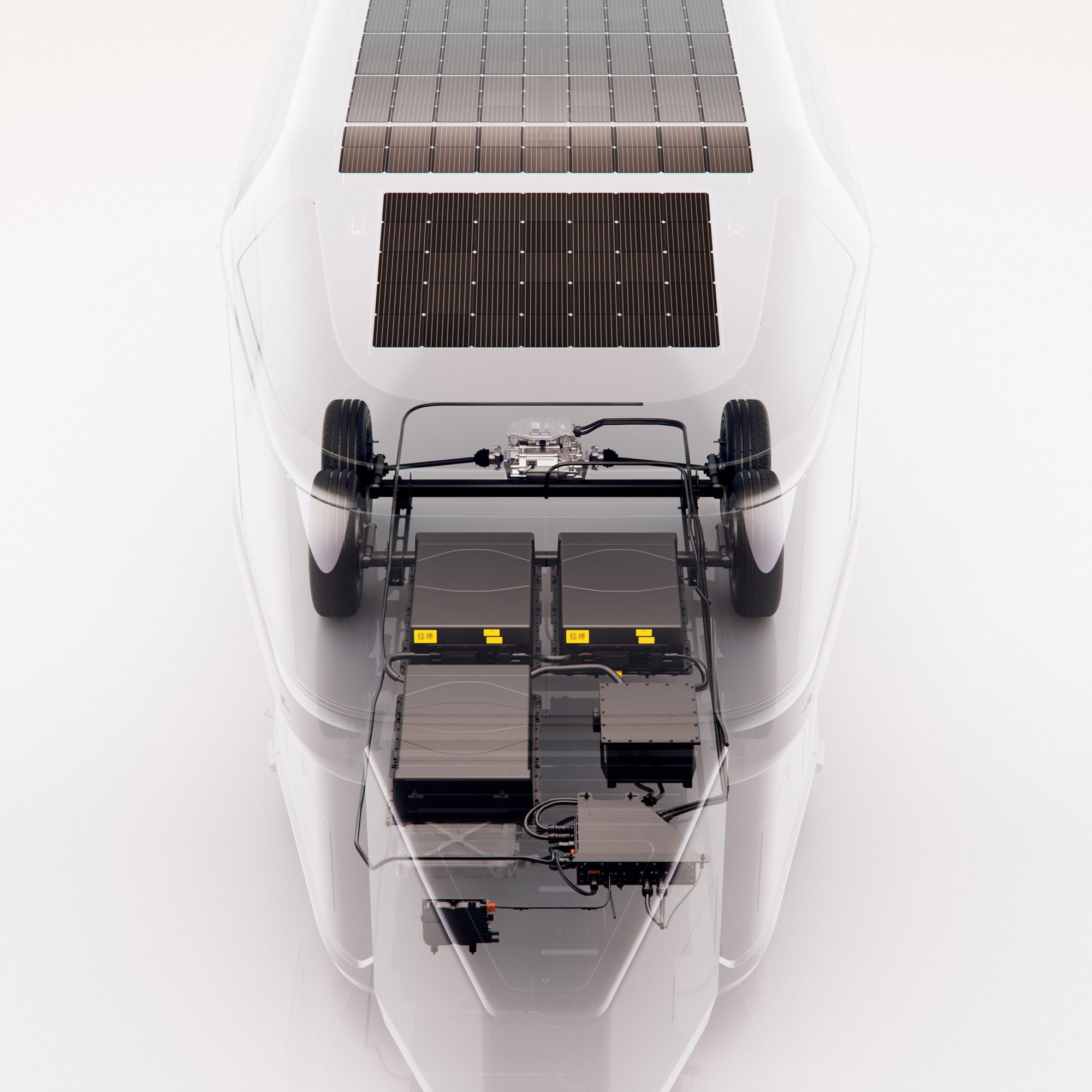

The two new models are powered by Lightship’s proprietary TrekDrive system, an intelligent propulsion technology that is designed to double the range (for an EV) or fuel efficiency (for an ICE) of the tow vehicle. Operating independently, the TrekDrive system senses acceleration, braking and cornering forces, then adjusts in real time.

The AE.1 Atmos features a 77 kWh battery system, 1.8 kW of integrated solar roof panels, and a starting price of $184,000.

The AE.1 Panos features a 44 kWh battery system and 840 W of integrated solar roof panels. It starts at $151,000.

Both models offer optional motorized awning and third bed add-ons. Customer deliveries are to begin in 2026.

“We’ve engineered these models to meet adventurers where they are,” explained Ben Parker, Lightship co-founder and Chief Product Officer. “Whether you’re planning extended off-grid expeditions or weekend getaways, there’s now an AE.1 designed specifically for your style of exploration.”

Source: Lightship