The US Department of Energy (DOE) has awarded $50 million to be invested over the next five years to establish the Low-cost Earth-abundant Na-ion Storage (LENS) consortium led by DOE’s Argonne National Laboratory to develop high-energy, long-lasting sodium-ion batteries.

The consortium includes six national laboratories and eight universities, which aim to develop sodium-ion batteries that will offer a more sustainable and lower-cost alternative to lithium-ion technology. They will seek to foster an industrial ecosystem for sodium-ion batteries in the US to diversify the supply of electric vehicle batteries and relieve supply chain concerns.

Dominant battery chemistries today include lithium, cobalt and nickel. Sodium, as an abundant element, can reduce risk by providing a wider variety of cost-effective options, Argonne noted. However, sodium-ion batteries store less energy per unit weight and volume, which results in a lower driving range—a barrier to competing with lithium-ion batteries.

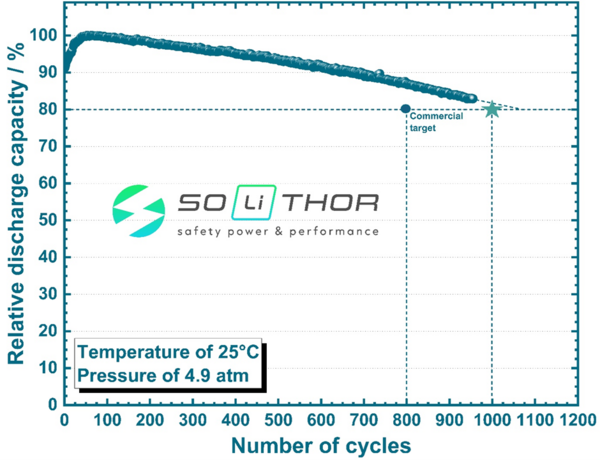

“The challenge ahead is improving sodium-ion energy density so that it first matches and then exceeds that of phosphate-based lithium-ion batteries while minimizing and eliminating the use of all critical elements,” said Venkat Srinivasan, Director of the LENS consortium and the Argonne Collaborative Center for Energy Storage Science (ACCESS). “Importantly, any improvements must not compromise other performance metrics such as cycle life and safety.”

The researchers from the consortium’s national laboratories and universities will work to discover and develop high-energy electrode materials, improve electrolytes, and design, integrate and benchmark battery cells.

An advisory board comprising well-established and emerging companies will provide industry perspectives and aim to nurture a US ecosystem for sodium-ion batteries.

DOE’s Brookhaven National Laboratory, Lawrence Berkeley National Laboratory, Pacific Northwest National Laboratory, Sandia National Laboratories and SLAC National Accelerator Laboratory are among the consortium’s participants.

Source: Argonne National Laboratory