The surge in electric vehicle adoption has spotlighted high-performance braided sleeving manufacturers as automakers push for solutions that can keep pace with rapidly advancing technology. With higher voltages, faster charging speeds and growing power demands, EV cables are under more stress than ever.

Cable protection prevents overheating, reduces wear from constant movement and ensures reliable energy transfer across the system. Beyond performance, proper sleeving and harness design directly impact safety and regulatory compliance. It is a top priority for manufacturers seeking to build vehicles that are efficient and trusted by consumers.

The Heat Challenge in EV Cables

High-voltage charging systems and the push for longer driving ranges expose EV cables to extreme temperatures that test the limits of traditional insulation. When insulation breaks down under the heat stress, it creates risks of resistance changes that can decrease resistance. This causes dangerous current surges, shortened battery life and even fire hazards.

To combat these threats, manufacturers use advanced materials — such as high-temperature polymers, specialized coatings and protective jackets — to withstand prolonged heat exposure and enhance thermal management. Precision winding techniques are also vital because they improve heat dissipation, which ensures cables remain reliable and safe under the harshest operating conditions.

Battling Vibrations in Harsh Conditions

Constant road vibrations put EV cables under continuous stress, often leading to gradual wear, tiny cracks in insulation and failures at connector points that can disrupt performance. These issues raise safety concerns and increase long-term maintenance costs for manufacturers and drivers. To reduce these risks, engineers use abrasion-resistant materials and reinforced harness designs that add strength and flexibility where needed.

In particular, braided sleeving for wire harnesses provides durable protection against friction and movement, ensuring cables remain secure and reliable in harsh driving conditions. By prioritizing vibration protection, EV makers can extend vehicle lifespan, improve system reliability and deliver more dependable electric mobility.

The Pressure to Reduce Weight

Lightweighting has become a central focus for EV manufacturers because every added kilogram directly impacts efficiency and driving range. Extra mass requires more energy for acceleration and hill climbing, which drains the battery faster and reduces the distance a vehicle can travel on a single charge. Engineers can explore lightweight materials, such as aluminum conductors, advanced composites and compact wire harnesses that reduce bulk without sacrificing performance.

The trade-off lies in ensuring these lighter options can still deliver the durability, safety and thermal resistance needed in demanding EV environments. Protective solutions like braided sleeving for wire harnesses support this balance by safeguarding slimmer, lighter designs against abrasion and wear. They allow suppliers to achieve efficiency gains without compromising reliability.

Innovations Driving EV Cable Protection

Innovations in EV cable protection transform how manufacturers meet rising performance and efficiency demands. Advanced polymers and nanomaterials are being developed with outstanding heat and chemical resistance, which allows cables to endure harsh conditions without breaking down. Meanwhile, smart cable systems with sensors enable real-time performance monitoring, allowing companies to detect faults early and prevent costly failures.

Modular harness designs are also becoming popular, helping reduce overall vehicle weight while simplifying assembly and maintenance processes. Adding to these advances, precision winding techniques ensure consistent cable structure and boost reliability, making them essential to next-generation EV design.

Leading EV Wire Harness Manufacturers

Choosing the correct wire harness supplier is critical for EV makers striving to balance performance and efficiency. Leading suppliers bring specialized expertise, advanced materials and innovative designs that help vehicles withstand the most challenging operating demands.

1. Atkins & Pearce

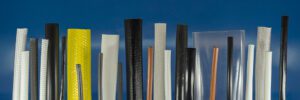

Atkins & Pearce stands out in EV wire harness solutions by offering a powerful blend of innovation and customization. With over 200 years of braided textile expertise, the company delivers expandable braided sleeving, electrical sleeving and tubing built from advanced fibers. It also offers functional coatings for thermal and abrasion resistance, ideal for high-voltage EV environments.

Its proprietary precision winding techniques ensure consistent cable structure and reliable performance, enhancing heat dissipation and reducing stress points. By choosing Atkins & Pearce, EV manufacturers gain a trusted partner that marries proven heritage with modern engineering and provides harness solutions that are durable and tailored to the evolving demands of electric mobility.

2. Yazaki

Yazaki delivers standout EV wire harness solutions rooted in nearly a century of innovation and unmatched control over every step. It ensures top-tier performance and reliability from raw material development to final production. Its custom-engineered harnesses smoothly integrate power and data networks with minimal splicing and durable connectors, which streamlines vehicle assembly and elevates system integrity.

Every hybrid vehicle on the road today includes at least one Yazaki high-voltage component — a harness, connector or charge coupler — demonstrating its industry leadership in safe, efficient electrified mobility. With a global presence spanning 46 countries, Yazaki offers responsive support and unmatched scale. It is a trusted partner for EV manufacturers seeking innovation and seamless implementation across markets.

3. LEONI

LEONI impresses EV suppliers with a wide range of high-performance wiring systems. These include high-voltage charging harnesses that support rapid charging and currents up to 1,000 amperes and auxiliary and traction harnesses engineered in copper or aluminum for efficient power delivery in demanding EV architectures. Its zonal harnesses simplify complexity by dividing wiring into modular sections, reducing weight and streamlining assembly without sacrificing functionality.

With full system integration and advanced solutions like rigid busbars for optimized heat dissipation and automated handling, LEONI brings scalability and innovation straight into the electrification era. Its 20 years of experience in electromobility, extensive research and development, and sustainability initiatives make it a reliable, future-ready partner in wiring solutions for EVs.

Meeting the Core Challenges of EV Cable Protection

Solving for heat, vibration and weight ensures EV performance and long-term reliability on the road. By leveraging advanced materials and working closely with trusted harness partners, companies can meet the growing technical demands of electrified mobility. Partnering with high-performance braided sleeving manufacturers strengthens cable protection, delivering durability and efficiency that keeps EV systems at their best.