Q&A with EV measurement engineering experts Coty Harrison and Cristian Loris of Yokogawa Test&Measurement.

When tasked with measuring the electrical power of complex systems like EVs, an inexperienced engineer may first reach for general instrumentation like oscilloscopes, data acquisition (DAQ) systems and digital multimeters (DMMs). While these instruments serve useful roles in electrical testing—oscilloscopes analyze time-dependent signals, DAQs handle large-scale data and DMMs focus on fundamental electrical measurements—they are not suited for making traceable and accurate electrical power measurements.

All three general tools suffer the same shortfalls—they are not designed to measure power accurately but instead accurately measure DC or, in some cases, clean AC RMS. Using oscilloscopes, DAQs and DMMs to measure power could compromise product design by creating significant (often invisible) measurement errors.

The right tool to measure power in complex EV systems is a purpose-built power analyzer that captures three core parameters—voltage, current and power—as well as a few very important additional parameters (depending on what system you are testing) that contribute to understanding the efficiency and overall system performance.

To learn more about purpose-built power analyzers, Charged recently chatted with measurement engineering experts Coty Harrison and Cristian Loris of Yokogawa Test&Measurement. Founded in 1911, Yokogawa is a global company that provides a range of products that measure electrical and optical signals and other critical engineering parameters. The company’s systems are used across industries like energy, manufacturing, and increasingly in EVs and renewable energy.

Charged: Can you give us a high-level explanation of why purpose-built power analyzers are critical in EV system development?

Coty Harrison: In EV applications, measurement accuracy must be reliably maintained across a range of frequencies and conditions, so it’s critical that you have a system that captures many different elements and channels.

We designed our newest power analyzers to provide precision with an error margin as low as 0.03%. This means manufacturers can confidently verify efficiency gains in the 1-2% range, which is critical for competitive advancements.

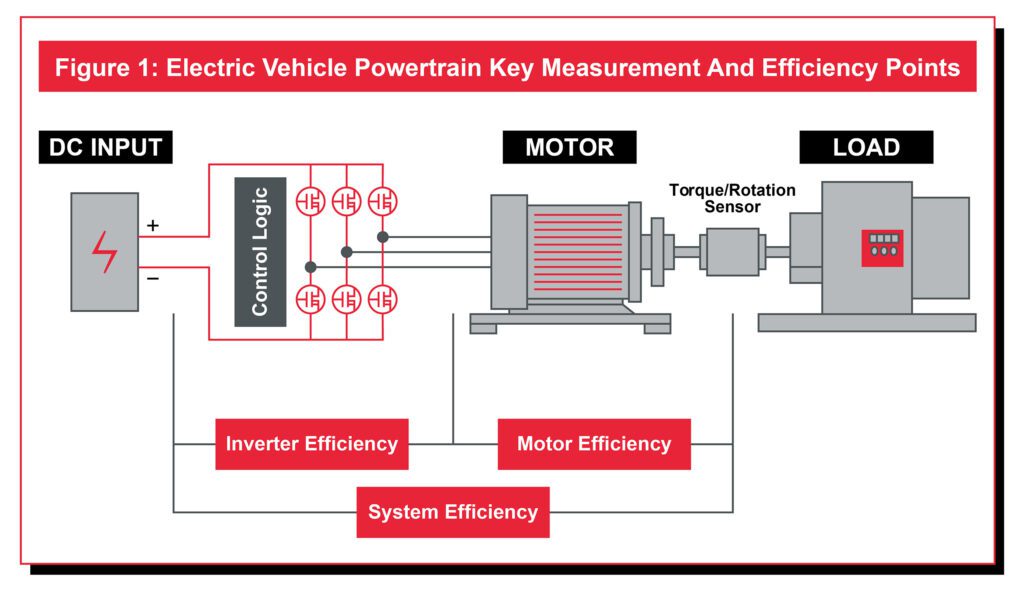

For example, in developing and testing a new EV traction motor design, you need a system that enables engineers to comprehensively measure electrical parameters as well as mechanical parameters like speed and torque.

Accuracy becomes especially important during validation, as manufacturers must ensure their products meet stringent efficiency and performance benchmarks before production or delivery to customers. As EVs gained traction and competition increased in the market, engineers began developing more innovative and complex designs, which meant more complicated measurements. For example, we designed our newest power analyzers to provide precision with an error margin as low as 0.03%. This means manufacturers can confidently verify efficiency gains in the 1-2% range, which is critical for competitive advancements.

New materials like silicon carbide (SiC) and gallium nitride (GaN) allow higher switching rates, so instruments also evolved to meet increasingly demanding switching requirements. For EV applications, it’s no longer a want but a need for a power analyzer to support sampling rates up to 10 mega samples per second (MSps) per channel. And when you combine that with 18-bit analog-to-digital (A/D) conversion, you ensure accurate data even under high-frequency conditions. This allows EV motor and inverter validation with efficiency measurements that differentiate between real gains and measurement inaccuracies—vital for performance tuning in automotive.

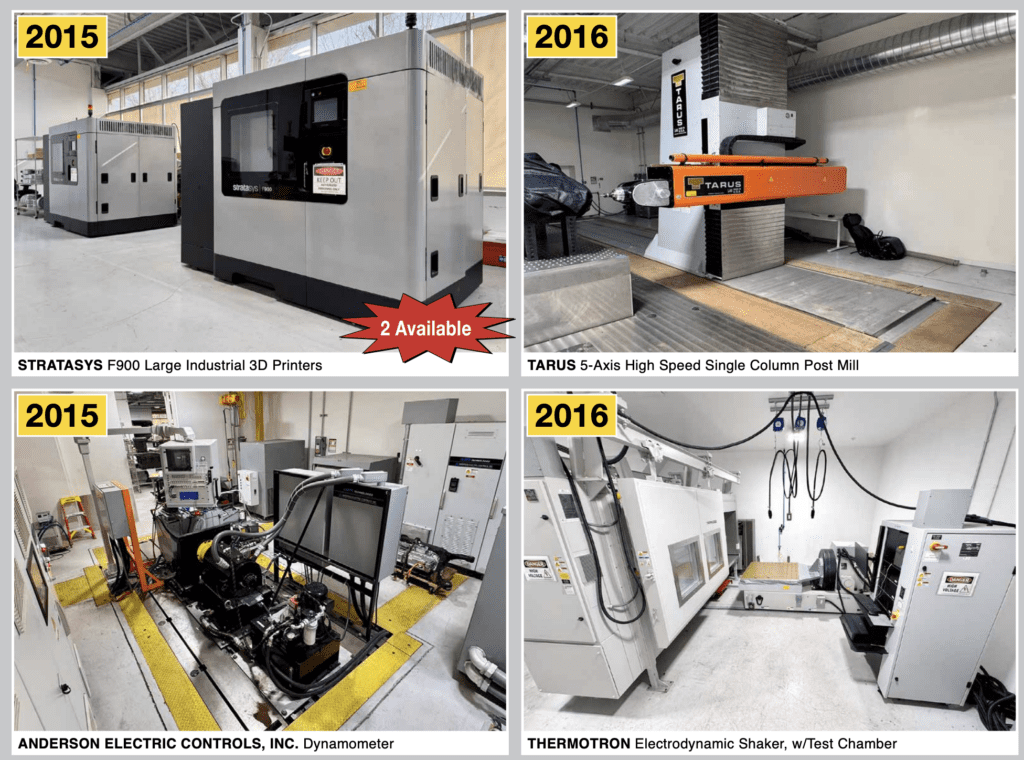

Figure 1: Electric Vehicle Powertrain Key Measurement And Efficiency Points

Charged: Can you expand on the example of EV traction motor design? How exactly is a purpose-built power analyzer used to improve the end product?

Cristian Loris: Efficiency directly impacts the range of EVs, which is a key factor for consumers. Small improvements in motor efficiency can significantly extend vehicle range and reduce energy consumption. Accurate measurements will optimize performance under various loads, and precision is especially critical when addressing complex drive cycle scenarios.

It comes down to two key challenges. First is measuring power to a known, traceable and guaranteed power spec, which isn’t possible if you are using instruments focused on DC specs or AC RMS. AC power—especially noisy switched power—requires integration at a high sample rate, consideration of line filters and zero crossings, etc.

The second challenge is that motors are an inductive load, which will always have some power factor that will further degrade measurement accuracy if you use general tools like oscilloscopes, DAQs and DMMs—as much as 30% or more.

Unlike general-purpose equipment, power analyzers will have dedicated algorithms optimized for traction motor applications, including power calculation over varying load conditions. For EV power measurements, signal conditioning is crucial to reduce noise and maintain signal integrity, especially in high-power systems. Also, purpose-built analyzers are designed to log data consistently over extended periods and offer traceable data records for certification purposes, which is important for EV powertrain testing that often involves long-duration measurements.

Harmonics and distortions in current and voltage waveforms lead to energy loss and may impact the performance of the EV motor. Power analyzers that can accurately measure harmonic content help engineers mitigate these losses.

Coty Harrison: To elaborate on this example, a few key parameters need to be measured in traction motor development. The first is powertrain efficiency, and those measurements require accurate voltage and current readings from the power supplied to the traction motor, both from the battery and the inverter. The challenge here lies in measuring high-frequency switching waveforms accurately, as traction motors typically operate in dynamic conditions.

Then there is the power factor, which impacts the energy transfer from the battery to the motor. Ensuring a higher power factor (as close as possible to the ideal unitary value) improves energy efficiency and reduces losses and is therefore crucial to measure and control.

Also, harmonics and distortions in current and voltage waveforms lead to energy loss and may impact the performance of the EV motor. Power analyzers that can accurately measure harmonic content help engineers mitigate these losses.

Finally, torque and speed measurements are essential to assess motor output accurately.

Combining the accurate measurement of these parameters will provide engineers with a complete picture of a motor’s efficiency.

Charged: You mentioned the validation stage of the development process. Is that when power analyzers are mainly used?

Cristian Loris: Yes, power analyzers are primarily used during the validation stage of EV systems to benchmark efficiency and ensure products meet performance expectations before moving into mass production.

Before finalizing designs and shipping parts to customers, manufacturers will use power analyzers to benchmark the parts with extremely high accuracy. This is when they create a spec sheet for a part. Ballpark values are insufficient for this step. They need to have exact power measurements.

Coty Harrison: The validation phase includes the component level (i.e. chip makers), the initial system integration level (i.e. Tier 1 suppliers), and the production level (i.e. vehicle OEMs)—to make sure the full production process is working correctly.

Generally, component manufacturers can use devices with lower accuracy (around 1%) while designing parts. And then before finalizing designs and shipping parts to customers, they will use power analyzers to benchmark the parts with extremely high accuracy. This is when they create a spec sheet for a part. Ballpark values are insufficient for this step. They need to have exact power measurements.

Charged: What Yokogawa products do EV engineers typically use for power analyzing?

Coty Harrison: Our Yokogawa WT series power analyzers are designed for this purpose. Unlike general measurement tools, our power analyzers provide both isolated voltage inputs and accurate current measurement capabilities, which are essential for accurately capturing cycle-by-cycle power metrics. Tools that lack AC signal testing will struggle with measurements in the dynamic conditions seen in EVs or other systems with shifting power factors.

Cristian Loris: As the automotive industry has embraced electrification, we’ve added features like support for multi-motor systems and faster sampling rates to handle higher switching frequencies.

Our WT5000 supports up to seven elements that provide accurate current and voltage measurements. Current sensing is performed using a shunt resistor with temperature and frequency compensation. For the evaluation of motor speed, torque and mechanical power, up to eight input channels (via two modules) are available, enabling the evaluation of four motor systems simultaneously.

Power analyzers provide both isolated voltage inputs and accurate current measurement capabilities, which are essential for accurately capturing cycle-by-cycle power metrics. Tools that lack AC signal testing will struggle with measurements in the dynamic conditions seen in EVs or other systems with shifting power factors.

Charged: Where are power analyzers used outside the EV Industry?

Cristian Loris: While automotive applications are driving a lot of innovation in the space, our power analyzers are also widely used in industrial motor development, which consumes roughly 60% of global electricity. So, enhancing efficiency in these systems has a massive impact on reducing energy usage and costs.

Charged: Can you tell us more about your roles at Yokogawa and how you help EV systems engineers?

Coty Harrison: I’ve been with Yokogawa for eight years. I started as an application engineer, which is where most of our technical staff begin. Given the complexity of our test equipment, it’s important to gain hands-on experience. From there, I transitioned into technical sales and eventually became the North American Sales Manager for our test and measurement team.

Cristian Loris: I also started with the application engineering team about two and a half years ago. There, I helped integrate our products into customers’ testing setups, allowing me to see firsthand the industry’s challenges. Since then, I have transitioned into the role of Product Manager for our decarbonization and electrification product portfolio, including our power analyzers for the EV market.

We work closely with EV systems engineers when they need help figuring out what testing products will work best for their specific applications, and then we help them customize and implement them into their processes.

MORE: Watch this webinar by Yokogawa Test&Measurement to learn more about how to effectively benchmark data for and troubleshoot issues with energy efficiency in EV powertrains.